Hitches and Towing 101

| CHAPTER CONTENTS | |

| 1. Introduction to Towing | 7. Brake Controls |

| 2. Towing Components | 8. Hitch Installation |

| 3. Types of Hitches | 9. Hooking Up |

| 4. Determining Tow Capacity | 10. Tow Bars/Dinghy Towing |

| 5. Selecting Your Hitch | 11. Towing Safety |

| 6. Wiring/Electrical | 12. Preparing Your Tow Vehicle |

Chapter 3 - Types of

Hitches

When you go shopping for towing equipment, one of the most bewildering choices you face is selecting a hitch. There are many different options available, and it's easy to become confused about the details of each kind and class of hitch.

Figure 3-1 shows the most common trailer hitch classes, with information about the maximum trailer weight and tongue weight allowed. In this figure "WC" stands for "Weight Carrying," meaning a basic ball mount and coupler. The "WD" ratings are higher, and those limits require you to use a Weight Distributing ball mount. "TW" stands for Tongue Weight, which is the weight on the trailer coupler when the trailer is fully loaded.

(click image to enlarge)

Figure 3-1: Class 1 Through Class 5 Trailer Hitch

Receivers

The receivers shown in Figure 3-1 are the most

commonly used towing solution. However, both lighter and heavier-duty options

are also available. The following definitions will help you understand the full

range of options. The definitions are listed in order from lightest duty to

heaviest, followed by definitions for Weight Carrying and Weight Distributing

hitches and Front Mount receivers.

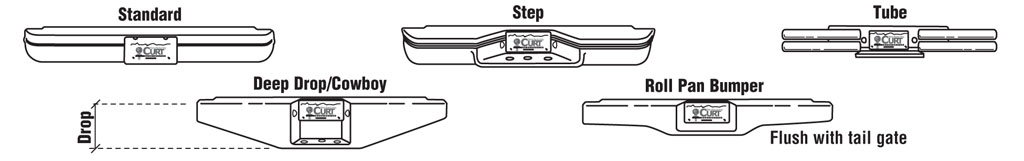

Bumper

Mount

The most basic trailer hitch for a passenger car, SUV, or truck is simply the

vehicle's bumper. Most truck bumpers and many SUV bumpers come equipped with a

hole in the center of the bumper sized to accommodate a standard trailer ball.

If your trailering needs are limited to less than 1,000 pounds and 100 pounds of

tongue weight, this style of hookup and some basic wiring may be all that you

need. Although some bumpers are rated for towing, use caution and never exceed

the capacity of the lowest rated towing component.

Bumper

Hitch

One of the problems with a Bumper Mount for a trailer ball is that unless you

purchase a quick-change trailer ball, you're limited to one ball size. Sooner or

later, you'll need to tow a trailer with a different-sized coupler. A light-duty

solution is a basic bumper hitch. These devices are available in a variety of

designs that bolt to your vehicle's bumper and provide a standard 2-inch ball

mount receiver and safety chain attachment points. While these devices resemble

a class 1-5 hitch, remember that they do not add any weight-bearing capacity to

your vehicle. Your basic bumper rating is still in effect. Weight distribution

hitches can not be used in conjunction with this type of

hitch.

Class 1-2 Receivers

These

light-duty receivers are generally designed for passenger cars and smaller

Crossover SUVs, but can be found for many makes and models. These classes use a

smaller 1 ¼-inch receiver tube for the ball mount. Class 1 hitches are rated to

tow trailers up to 2,000 pounds with 200 pounds of tongue weight, and Class 2

can handle 3,500 pound trailers with 350 pounds of tongue weight. It's important

to remember, however, that these hitches do not increase the total weight that a

given vehicle can tow.

Class 3

Receivers

The

most common receiver class installed on full-size pickup trucks and SUVs. If

your full-size truck is equipped with a tow package, it's probably a Class 3.

These receivers have a 2-inch square receiver tube. Class 3 receivers can handle

up to 8,000 pound trailers and 800 pounds of tongue weight with a weight

carrying ball mount, or up to 12,000 pounds and 1,200 pounds of tongue weight

with a weight distributing hitch. This generally exceeds the towing capacities

of most non-commercial vehicles, so a Class 3 hitch is rarely the limiting

factor when towing.

Class 4-5 Receivers

Add

new XD hitches and include increased capacity in copy below.

These receivers

are the heaviest-duty trailer hitches that can be installed at the rear of a tow

vehicle. A Class 4 hitch can carry 10,000 pounds and 1,000 pounds of tongue

weight with a weight carrying hitch, or up to 12,000 and 1,200 pounds with a

weight distributing hitch. Class 5 receivers can carry up to 14,000 pounds and

1,400 pounds tongue weight. Need to corrent the following sentence - Class 4

& 5 receivers use the same 2-inch receiver tube as a Class 3, but

some Class 5 receivers use a 2 ½-inch receiver tube. To go beyond the

capacity of a Class V receiver, you need to install a Gooseneck or Fifth Wheel

design that places the trailer's tongue weight in front of a pickup truck's rear

axle.

Fifth Wheel Hitch

These heavy-duty hitches mount in a pickup or commercial truck bed forward of

the rear axle. Fifth wheel hitches are similar in design to those used by

commercial 18-wheeler tractor-trailer rigs. Fifth wheel trailer capacities range

from 16,000 to 30,000 pounds and up to 5,000 pounds of pin weight (tongue

weight), depending on the design of the hitch, and the rating by the

manufacturer. Fifth wheel hitches are commonly used in large

campers, or travel trailers, and car haulers. Fifth wheel trailers are

prized for their ease of maneuverability and stability, which is why they're a

common choice for large campers. Most fifth wheel hitches have some "pivot"

capabliltiy to absorb bumps and contours of the road. Fifth wheel hitches are

the only type of hitch where the coupling device is part of the hitch and not

the trailer.

Gooseneck Hitch

Like the fifth wheel, this hitch design moves the trailer's tongue weight forward of a pickup truck's rear axle. The Gooseneck ball mounts vertically on the truck bed. Some designs can be folded down or quickly removed to allow full access to the truck bed when the trailer is not hooked up. Only trailers designed for use with a Gooseneck hitch can connect to this style of hitch, and they cannot connect to any other style of hitch.

Typical applications for a gooseneck include livestock trailers, car

& toy haulers, and industrial/commercial trailers. Gooseneck

hitches can haul up to about 30,000 pound trailers with 6,000 pounds of tongue

weight. Goosenecks are typically installed on 1-ton trucks with dually (4 wheel)

rear axles to handle that level of weight. Gooseneck hitches cannot be installed

on passenger cars, SUVs, vans, or RVs, but are frequently installed on

commercial truck conversions.

Weight Carrying

Hitch

Any ball mount inserted into a receiver of any class, or a ball installed on

a bumper or bumper hitch is considered a weight carrying hitch. The name means

that all of the trailer's tongue weight is being carried on the ball and

receiver. Tongue weight is one of the key limits to any receiver's towing

capability, so weight carrying hitches cannot pull as much trailer weight as a

weight distributing hitch installed on the same receiver. Weight distributing

hitches add stability and increase the towing capacity of most weight carrying

hitches.

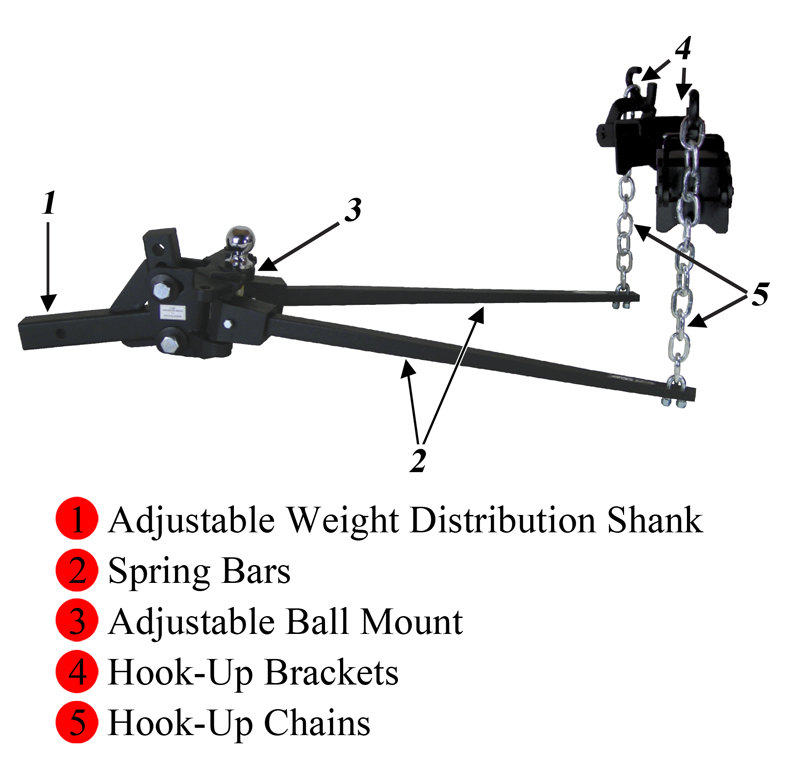

Weight Distributing Hitch

A

weight distributing hitch (also called a "load equalizing hitch") is designed to

distribute the tongue weight of a trailer across all four wheels of the tow

vehicle. Weight distributing hitches are used in the same Class 3-5 receivers as

a weight carrying hitch. Any vehicle with a Class 3-5 receiver can use a weight

distributing hitch. There are a couple of key differences between these units

and weight carrying models. The main difference is that a weight distributing

hitch uses long rods called "spring bars" ( #2 on the schematic above) to

exert leverage on your tow vehicle's frame, transferring some of the tongue

weight to the vehicle's forward wheels. Without a weight distributing hitch,

heavy tongue weight tends to lift the tow vehicle's front wheels and weigh down

the vehicle's rear end. With a weight distributing hitch, your entire towing rig

will ride level and be more stable on the road. Weight distributing hitches are

also adjustable for different trailer heights. You can also add sway controllers

to a weight distributing hitch. While WD hitches can help reduce some sway, they

are notsway controls themselves. Only a sway control can

significantly reduce or eliminate sway.

A

weight distributing hitch (also called a "load equalizing hitch") is designed to

distribute the tongue weight of a trailer across all four wheels of the tow

vehicle. Weight distributing hitches are used in the same Class 3-5 receivers as

a weight carrying hitch. Any vehicle with a Class 3-5 receiver can use a weight

distributing hitch. There are a couple of key differences between these units

and weight carrying models. The main difference is that a weight distributing

hitch uses long rods called "spring bars" ( #2 on the schematic above) to

exert leverage on your tow vehicle's frame, transferring some of the tongue

weight to the vehicle's forward wheels. Without a weight distributing hitch,

heavy tongue weight tends to lift the tow vehicle's front wheels and weigh down

the vehicle's rear end. With a weight distributing hitch, your entire towing rig

will ride level and be more stable on the road. Weight distributing hitches are

also adjustable for different trailer heights. You can also add sway controllers

to a weight distributing hitch. While WD hitches can help reduce some sway, they

are notsway controls themselves. Only a sway control can

significantly reduce or eliminate sway.

Front Mount

Hitch

For

certain applications, having a trailer hitch receiver at the front of your

vehicle may be convenient. For example, a front-mounted hitch allows you to

easily use a boat ramp by maintaining close control of your trailer. Front mount

hitches may be of any class, and are easily installed on most full-size pickup

trucks, vans and SUVs.

| << Back to Chapter 2 | Go to Chapter 4 >> |